Investigation on dynamic hardness and high strain rate indentation size effects in aluminium (110) using nano-impact

纳米冲击作为一种高应变率的摆式压痕技术,已广泛应用于获取材料在往复接触过程中的局部动态力学响应。相比之下,通过分析单一高应变率冲击来获得应变率敏感性的量化信息的方法还不够完善,迫切需要找到一种切实可靠的方法在纳米和微尺度上测定动态硬度。

Nano-impact, a high strain rate pendulum-based indentation technique, has been widely used to extract the local dynamic mechanical response of materials in repetitive contact. In contrast the analysis of single high strain rate impacts to obtain quantitative information on strain rate sensitivity is less well developed. A robust and reliable method for determining dynamic hardness at the nano- and micro-scale is highly desirable.

最近,东南大学的孙正明、陈坚教授课题组(共同通讯作者)利用纳米冲击系统研究了铝(110)的动态硬度,提出了压入过程中的尺寸效应也具有应变速率敏感性,并实验观测到了该效应。该文章发表在国际力学领域的权威期刊Mechanics of Materials上,这是东南大学材料学院首次在该期刊上发表研究成果。博士研究生秦立光为该论文的第一作者。

Recently, Sun and Chen group in Southeast University reported an investigation of nano-impacts with different accelerating force and distance on a sample of single crystal Al (110) to study the dynamic hardness and its size effects. it is proposed that the size effect in the indentation process also has strain rate sensitivity and the effect has been observed experimentally. These finds have been published in a leading international journal in the field of mechanics: Mechanics of Materials. This is the first time that the school of Materials Science and Engineering of Southeast University has published the research results in this journal. The Ph.D. candidate Liguang Qin is the first author.

全文链接:https://www.sciencedirect.com/science/article/pii/S0167663618304319(点击跳转到文章页)

核心内容如下:

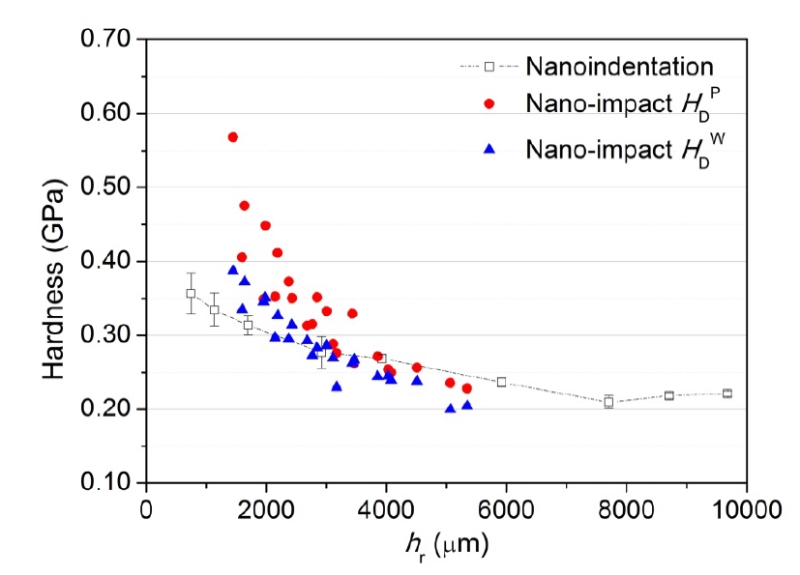

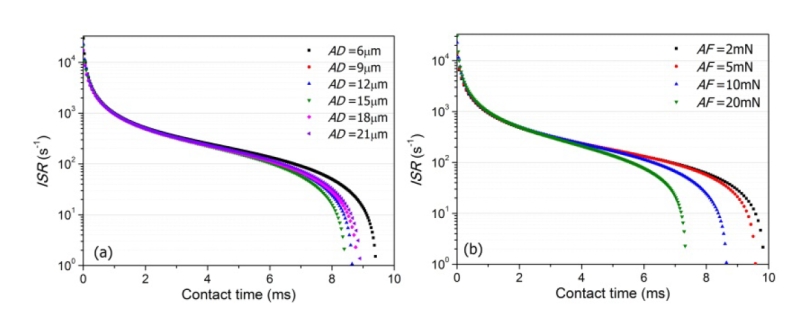

本实验研究以单晶Al(110)为研究对象,研究了不同加速力和距离下的纳米冲击对其动态硬度和尺寸效应的影响。基于记录峰值力与压痕投影面积的比值,将常用的基于能量的动态硬度法与迈耶硬度法二者进行了比较,。结果表明,两种方法在较大的压入深度下均表现出较大的相似值,但由于系统中不可避免的能量耗散,能量法在低冲击功下的可靠性较差。动态压痕尺寸效应比准静态压痕试验更为明显。这种动态效应是由于接触过程中高应变率及其快速变化引起的局部应变所致。并且 实验发现在最高冲击能作用下应变软化的转变可能是由于局部应变在严重冲击条件下产生的绝热效应。

In the present work,nano-impacts with different accelerating force and distance were carried out on a sample of single crystal Al (110) to study the dynamic hardness and its size effects.The common energy-based approach for dynamic hardness has been compared with an approach using Meyer's hardness corresponding to the ratio of the recorded peak force and the projected area of the indentation. It was found that both methods showed broadly similar values at larger penetration depth, but the energy approach became less reliable at the low impacting energy due to unavoidable energy dissipation in the system. Dynamic indentation size effects have been identified which were more pronounced than those in quasi-static indentation tests. This dynamic effect has been attributed to the localized strain caused by the high strain rate and its rapid change during contact. At the highest impact energies studied a transition into strain softening was also identified which is probably due to the adiabatic effects caused by the localized strain under severe impacting conditions.

图1 不同模型获得的动态硬度

图2 实验中发现的尺寸效应具有应变速率敏感性

更多学术成果介绍: