| 基 本 信 息 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 姓名:朱鸣芳 性别:女 职称:教授、博导 Email:zhumf@seu.edu.cn 办公电话:025-83793355 工作地点:材料楼A-340 通讯地址:南京市江宁区东南大学材料学院 | 研究方向: 材料成分设计和组织性能的模拟预测 材料加工过程多场和多尺度耦合的数值模拟 纳米功能材料表面性能的模拟预测 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 个 人 简 介 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

主持国家自然科学基金面上项目5项、教育部基金2项、中美和中韩国际合作项目7项等。从2001年以来以第一作者或通讯作者在国内外著名杂志以及国际会议上发表学术论文120余篇。 课程教学 材料数值模拟基础(本科生) 材料加工过程数值模拟(研究生) 教育经历 • 1992.9-1996.1, 东南大学, 机械工程系, 博士 • 1989.9-1992.3, 东南大学, 材料科学与工程系, 硕士 • 1978.3-1982.1, 浙江大学, 材料科学与工程系, 学士

研究工作经历 • 2002.8-今, 东南大学, 机械系/材料学院, 教授 • 1999.8-2002.8, 韩国延世大学, 冶金系, 博士后/研究教授 • 1996.1-1999.7, 东南大学, 机械工程系, 讲师/副教授 • 1982.2-1989.8, 江苏省铸造热处理研究所, 热处理研究室, 助工/工程师 研究内容及代表性成果 1. 凝固显微组织演化的数值模拟

Al-7 wt.%Cu等轴晶粒组织在TGZM作用下的显微组织演化的CA模拟

枝晶粗化

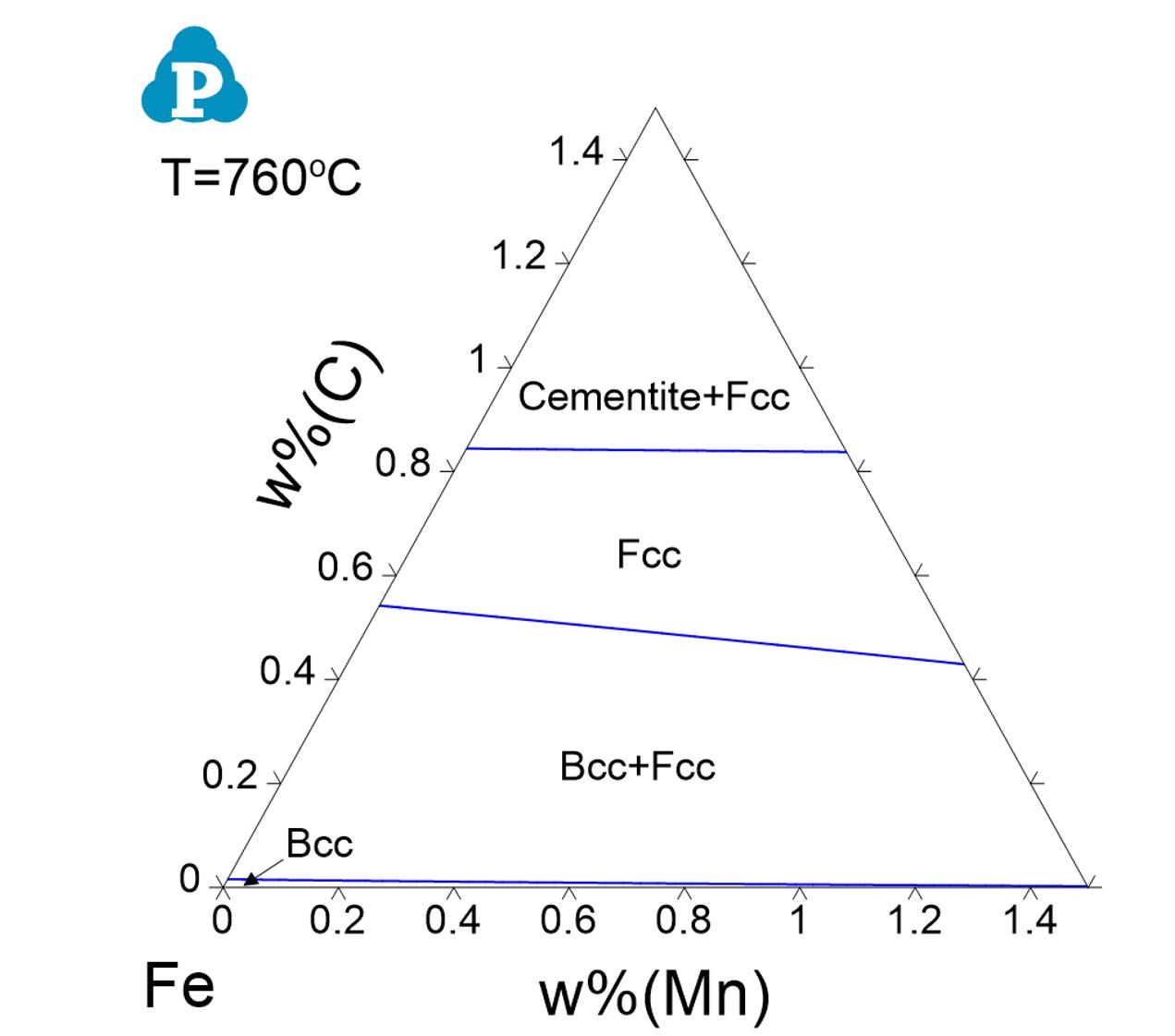

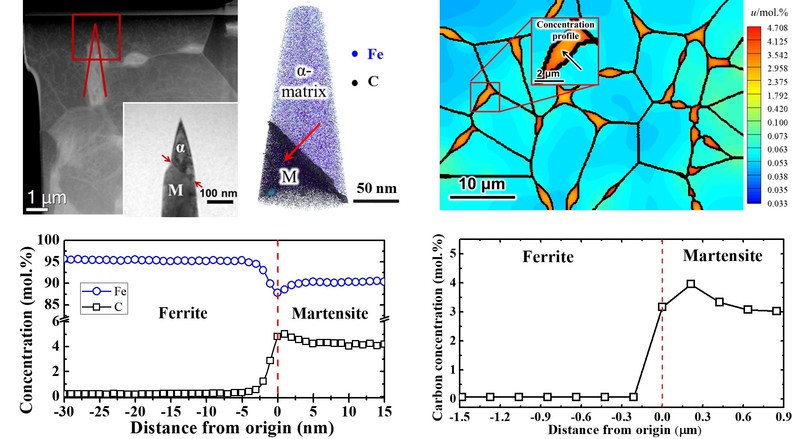

2. 材料成分设计和固态相变模拟

双相钢马氏体内碳浓度模拟预测值与APT实验对比 3. 材料加工过程的多尺度数值模拟

4.纳米结构表面超疏水性能的模拟预测

国际国内合作 与德国耶拿国大学Markus Rettenmayr教授课题组、德国马普学会钢铁研究所DierkRaabe教授、美国西北大学David Seidman教授课题组、美国俄亥俄州立大学Doru M. Stefanescu教授、韩国延世大学Chunpyo Hong教授、美国普渡大学Qingyou Han教授、美国AO Smith公司、美国CompuTherm公司等国内外著名学者、研究机构和公司建立有密切的学术合作关系。 主要发表论文目录 •Lin Xian, Zou Xinyi, An Dong, Krakauer Bruce W., Zhu Mingfang*, Multi-Scale Modeling of Microstructure Evolution during Multi-Pass Hot-Rolling and Cooling Process, Materials, 2021, 14(11): 2947. •Hu Mengdan, Wang Taotao, Fang Hui, Zhu Mingfang*, Modeling of gas porosity and microstructure formation during dendritic and eutectic solidification of ternary Al-Si-Mg alloys. J. Mater. Sci. Technol., 2021, 76: 76-85. •Fang Hui, Xue Hua, Zhang Qingyu, Pan Shiyan, Hu Mengdan, Zhu Mingfang*, Modeling of dendrite arm fragmentation and dendrite arm coarsening. Eur. Phys. J. E, 2020, 43(7): 44. •Zhang Qingyu*, Sun Dongke, Wang Zhijun, Wang Hui, Zhu Mingfang*, Modeling of microporosity formation and hydrogen concentration evolution during solidification of an Al-Si alloy, Chin. Phys. B, 2020, 29(7): 078104. •An Dong, Baik Sung-Il, Ren Qingqiang, Jiang Ming, Zhu Mingfang*, Isheim Dieter, Krakauer Bruce W., Seidman David N., Seidman David N.*, A transmission electron microscopy and atom-probe tomography study of martensite morphology and composition in a dual-phase steel, Mater. Charact., 2020, 162: 110207. •Hu Mengdan, Sun Chang, Fang Hui, Zhu Mingfang*, Competitive dendrite growth during directional solidification of a transparent alloy: Modeling and experiment. Eur. Phys. J. E, 2020, 43(3): 16. •Fan Yiming, Fang Hui, Tang Qianyu, Zhang Qingyu, Pan Shiyan, Zhu Mingfang*, Cellular automaton modeling of peritectic transformation. Eur. Phys. J. E, 2020, 43(3): 17. •An Dong, Pan Shiyan, Ren Qingqiang, Li Qian, Krakauer Bruce, ZhuMingfang*, A Gibbs energy balance model for the isothermal ferrite-to-austenite transformation, Scripta Mater.,2020, 178: 207-210. •Zhang Qingyu, Sun Dongke, Pan Shiyan, Zhu Mingfang*, Microporosity formation and dendrite growth during solidification of aluminum alloys: Modeling and experiment, Int. J. Heat Mass Transfer, 2020, 146: 118838. •An Dong, Chen Shuanglin, Sun Dongke, Pan Shiyan, Krakauer Bruce W., ZhuMingfang*, A cellular automaton model integrated with CALPHAD-based thermodynaic calculations for ferrite-austenite phase transformations in multicomponent alloys, Comp. Mater. Sci., 2019, 166: 210-220. •方辉, 薛桦, 汤倩玉, 张庆宇, 潘诗琰, 朱鸣芳*, 定向凝固糊状区枝晶粗化和二次臂迁移的实验和模拟, 金属学报, 2019, 55(5): 664-672. •方辉, 薛桦, 汤倩玉, 张庆宇, 潘诗琰, 朱鸣芳*, 温度梯度区域熔化作用下熔池迁移的元胞自动机模拟, 物理学报, 2019, 68(4): 048102. •胡梦丹, 张庆宇, 孙东科, 朱鸣芳*, 纳米结构超疏水表面冷凝现象的三维格子玻尔兹曼方法模拟, 物理学报, 2019, 68(3): 030501. •Fang Hui, Tang Qianyu, Zhang Qingyu, Gu Tengfei, Zhu Mingfang*, Modeling of microstructure and microsegregation formation during solidification of Al-Si-Mg alloys, Int. J. Heat Mass Transfer, 2019, 133: 371-381. •An Dong, Baik Sung-Il, Pan Shiyan, Zhu Mingfang*, Isheim Dieter, Krakauer Bruce W., Seidman David N., Evolution of Microstructure and Carbon Distribution During Heat Treatments of a Dual-Phase Steel: Modeling and Atom-Probe Tomography Experiments, Metall. Mater. Trans. A, 2019, 50(1): 436-450. •Pan Shiyan*, Zhu Mingfang*, Growth of homogeneous mixed A1-xBx bulk crystals: Analytical prediction, phase-field modeling and experiment comparison,Materialia,2019, 5: 100247. •Pan Shiyan, Zhu Mingfang*, Peritectic transformation with non-linear solute distribution in all three phases: Analytical solution, phase-field modeling and experiment comparison, Acta Mater., 2018, 146: 63-75. •Zhang Qingyu, Fang Hui, Xue Hua, Tang Qianyu, Pan Shiyan, Rettenmayr Markus, Zhu Mingfang*, Modeling of melting and resolidification of equiaxed microstructures in a temperature gradient, Scripta Mater., 2018, 151: 28-32. •Zhang Qingyu, Wang Taotao, Yao Zhengjun, Zhu Mingfang*, Modeling of hydrogen porosity formation during solidification of dendrites and irregular eutectics in Al–Si alloys, Materialia, 2018, 4: 211-220. •Zhang Qingyu, Zhu Changsheng, Zhu Mingfang*, Three-dimensional numerical simulation of droplet evaporation using the lattice Boltzmann method based on GPU-CUDA accelerated algorithm, Commun. Comput. Phys., 2018, 23(4): 1150-1166. •Zhang Qingyu, Xue Hua, Tang Qianyu, Pan Shiyan, Rettenmayr Markus, Zhu Mingfang*, Microstructural evolution during temperature gradient zone melting: Cellular automaton simulation and experiment, Comp. Mater. Sci., 2018, 146: 204-212. •朱鸣芳*, 邢丽科, 方辉, 张庆宇, 汤倩玉, 潘诗琰, 合金凝固枝晶粗化的研究进展, 金属学报, 2018, 54(5): 789-800. •Pan Shiyan, Zhu Mingfang*, Rettenmayr Markus, A phase-field study on the peritectic phase transition in Fe-C alloys, Acta Mater., 2017, 132: 565-575. •Zhang Qingyu, Fang Hui , Xue Hua, Pan Shiyan, Rettenmayr Markus, Zhu Mingfang*, Interaction of local solidification and remelting during dendrite coarsening-modeling and comparison with experiments, Sci.Rep., 2017, 7: 17809. •Zhang Qingyu, Lippmann Stephanie, Grasemann Aaron, ZhuMingfang, Rettenmayr Markus*, Determination of temperature dependent thermophysical properties using an inverse method and an infrared line camera, Int. J. Heat Mass Transfer, 2016, 96: 242-248. •Zhang Qingyu, Sun Dongke, Zhu MingFang*, A multicomponent multiphase lattice Boltzmann model with large liquid–gas density ratios for simulations of wetting phenomena, Chin. Phys. B, 2017, 26(8): 084701. •He Lei, RuanRuijie, LinChen, Dai Ting, Hu Xianjun, Krakauer Bruce W., Zhu Mingfang*, Study of the dynamic strain-induced transformation process of a low-carbon steel: experiment and finite element simulation, Adv. Mater. Sci. Eng., 2016, 2016: 1927504. •Zhang Qingyu, Sun Dongke, Zhang Youfa, Zhu Mingfang*, Numerical modeling of condensate droplet on superhydrophobic nanoarrays using the lattice Boltzmann method, Chin. Phys. B, 2016, 25(6): 066401. •朱鸣芳*, 汤倩玉, 张庆宇, 潘诗琰, 孙东科, 合金凝固过程中显微组织演化的元胞自动机模拟, 金属学报, 2016, 52(10): 1297-1310. •Zhu Mingfang*, Zhang Lei, Zhao Honglei, StefanescuDoru M., Modeling of microstructural evolution during divorced eutectic solidification of spheroidal graphite, Acta Mater., 2015, 84: 413-425. •Pan Shiyan, Zhang Qingyu, Zhu Mingfang*, Rettenmayr Markus, Liquid droplet migration under static and dynamic conditions: Analytical model, phase-field simulation and experiment, ActaMater., 2015, 86: 229-239. •Zhang Qingyu, Sun Dongke, Zhang Youfa*, ZhuMingfang*, Lattice Boltzmann modeling of droplet condensation on superhydrophobic nanoarrays, Langmuir, 2014, 30(42): 12559-12569. •ZhuMingfang*, Sun Dongke, Pan Shiyan, Zhang Qingyu, RaabeDierk, Modelling of dendritic growth during alloy solidification under natural convection, Modell. Simul. Mater. Sci. Eng., 2014, 22(3): 034006. •An Dong, Pan Shiyan, Huang Li, Dai Ting, Krakauer Bruce, ZhuMingfang*, Modeling of ferrite-austenite phase transformation using a cellular automaton model, ISIJ Int., 2014, 54(2): 422-429. •ZhuMingfang*, Li Zhengyang, An Dong, Zhang Qingyu, Dai Ting, Cellular automaton modeling of microporosity formation during solidification of aluminum alloys, ISIJ Int., 2014, 54(2): 384-391. •Zhang Xianfei*, Zhao Jiuzhou*, Jiang Hongxiang, ZhuMingfang, A three-dimensional cellular automaton model for dendritic growth in multi-component alloys, Acta Mater., 2012, 60(5): 2249-2257. •Pan Shiyan, Zhu Mingfang* , A three-dimensional sharp interface model for the quantitative simulation of solutal dendritic growth, ActaMater., 2010, 58(1): 340-352. •ZhuMingfang*, Pan Shiyan, Sun Dongke, Zhao Honglei, Numerical simulation of microstructure evolution during alloy solidification by using cellular automaton method, ISIJ Int., 2010, 50(12): 1851-1858. •Sun Dongke, Zhu Mingfang*, Pan Shiyan, RaabeDierk, Lattice Boltzmann modeling of dendritic growth in a forced melt convection, Acta Mater., 2009, 57(6): 1755-1767. •Zhu Mingfang*, StefanescuDoru M., Virtual front tracking model for the quantitative modeling of dendritic growth in solidification of alloys, Acta Mater., 2007, 55(5): 1741-1755. •ZhuMingfang*, Hong Chunpyo, StefanescuDoru M., Chang Y. Austin, Computational modeling of microstructure evolution in solidification of aluminum alloys, Metall. Mater. Trans. B, 2007, 38(4): 517-524. •ZhuMingfang*, Cao Weisheng, Chen Shuanglin, Hong Chunpyo, Chang Y. Austin, Modeling of microstructure and microsegregation in solidification of multi-component alloys, J. Phase Equilib. Diffus., 2007, 28(1): 130-138. •ZhuMingfang*, Hong Chunpyo, Modeling of irregular eutectic microstructures in solidification of Al-Si alloys, Metall. Mater. Trans. A, 2004, 35A(5): 1555-1563. •ZhuMingfang*, Lee Sungyoon, Hong Chunpyo, Modified cellular automaton model for the prediction of dendritic growth with melt convection, Phys. Rev. E, 2004, 69(6): 061610. •ZhuMingfang*, Hong Chunpyo , Modeling of microstructure evolution in regular eutectic growth, Phys. Rev. B, 2002, 66(15): 155428. •ZhuMingfang*, Hong Chunpyo , A modified cellular automaton model for the simulation of dendritic growth in solidification of alloys, ISIJInt., 2001, 41(5): 436-445. •ZhuMingfang*, Kim Jiemin, Hong Chunpyo , Modeling of globular and dendritic structure evolution in solidification of an Al-7mass%Si alloy, ISIJInt., 2001, 41(9): 992-998. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||